In plenty of recent articles I’ve been writing about the right way to go about selecting alternative rubber for your fourbie. I deliberately steered clear of touching on the mysteries of tyre pressure, because it’s a subject deserving of its own blog, so here it is.

I’ll make my opening salvo a topical one, because I expect that Loaded 4X4 Media is going to be inundated with hate mail, as everyone will have an opinion.

Sorry. Most of you will be wrong.

I firmly believe…“The best starting point for on-road pressure advice for your 4WD will be found in your tyre placard”.

BOOM!

I can hear the first mortar shell landing now!

Despite what many people think about vehicle manufacturers and the pressure settings they employ on their placards, they aren’t dumb. The complexities of designing and building a modern motor vehicle are huge and way beyond most of us, especially when it comes to engineering expertise.

Tyres are a big deal, they too rely heavily on professional guidance for that advice and it comes in the form of solid science. Without science and fact, when put to the test in a court of law, a judgment against a corporation will be hugely expensive. In this litigious world we live in, everything these days has to be verifiable.

In every motor-vehicle building jurisdiction around the world, is a professional group of tyre and wheel makers. In Australia the gather is known as the Tyre and Rim Association of Australia (or TRAA).

Each year they publish a fascinating bible referred to simply as the “Manual”. In it is a compendium of charts and figures detailing the loads that can be carried and at what pressures they should be set, as well as detailed facts on appropriate wheel size for different tyre sizes. It covers everything from wheelbarrows, to motorcycles, to earth moving equipment, to trucks and light vehicles like a 4WD.

It is this book where vehicle makers get their baseline points for the on-road recommendations for we, the end users. Some vehicle makers go the extra yards and do additional testing where their vehicles might be exposed to heavier or lighter loads due to an accessory fitout, or some unique road/operational condition that’ll demand a variation. That could be an increase in pressure (or a decrease), but their placard will be right for that particular vehicle and its originally designed brief and expected loads along with the tyre selected to do the job. The tyres will likely be of P (Passenger) construction too, because 90% of 4WDs sold in this country never stray from a bitumen road.

Let’s have a look at a couple of examples.

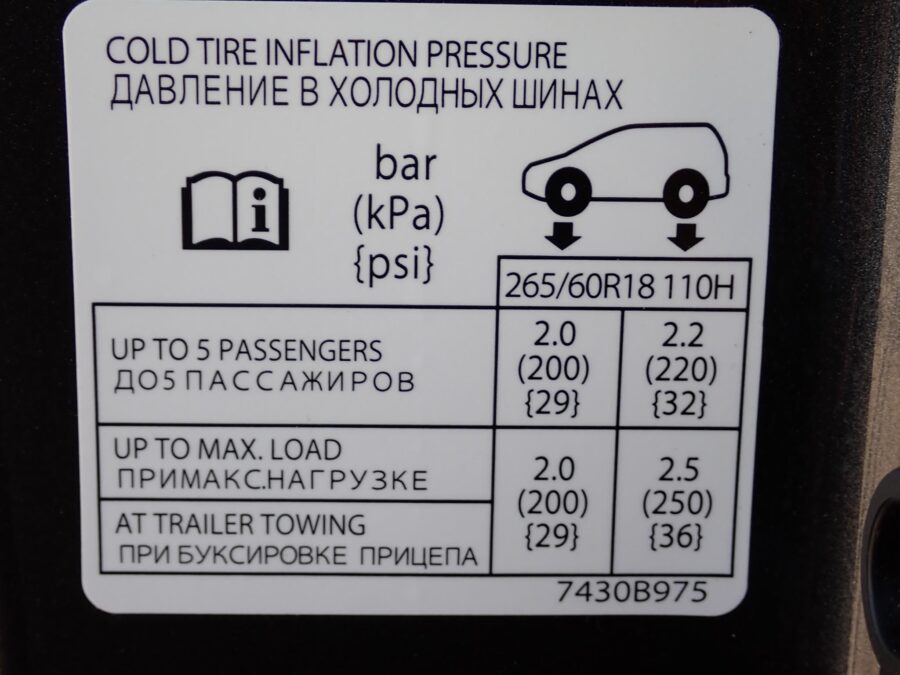

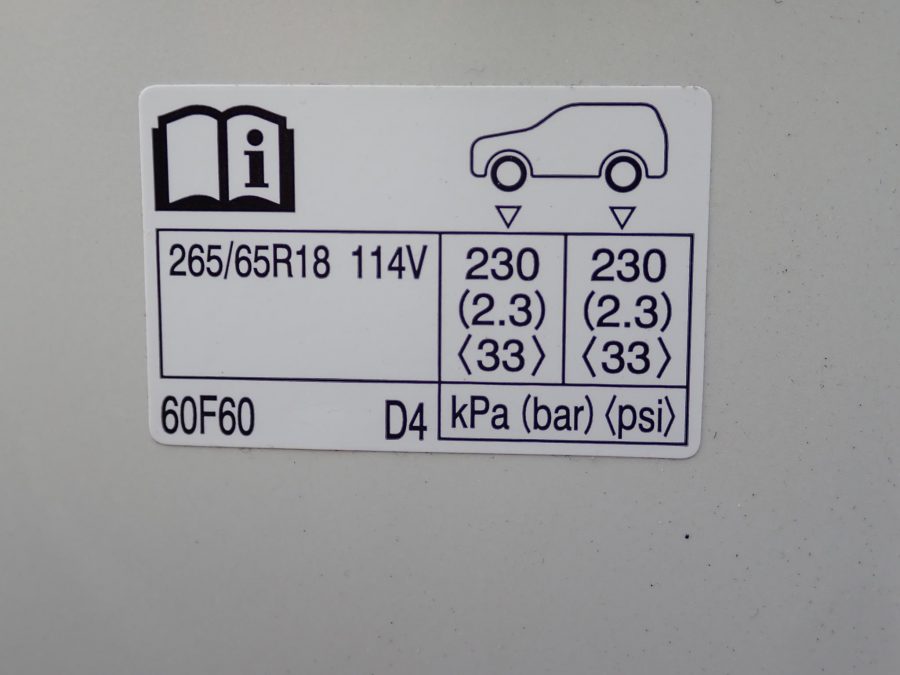

Most medium sized wagons (Isuzu MU-X, Mitsubishi Pajero and Sport, Toyota Prado and Fortuner and the like) have a placard that states on average a 200-220kPa range (that’s 29-32psi) front and rear and sometimes irrespective of the load.

Most medium sized utes (Isuzu D-MAX, Mitsubishi Triton, Toyota Hilux, Ford Ranger) have a placard that states the same 200-220kPa range for the front tyres and up to 250kPa (36psi) or more, perhaps 300kPa (43psi) (for a commercial heavy variant) for the rears. Notice I said “up to”.

Whilst a 4WD wagon’s load will be pretty constant (a mass of motor, transmission and passengers sitting over the front axle that is unlikely to change much) with a modest cargo space in the rear (that will fill up with passengers and their sundry gear), the pressures suggested remain usually the same, laden versus unladen and front to rear, because the loads will be similar.

A ute is a significantly different prospect however, with a big change seen from empty to full and that’s why the back tyres get the boost. The fronts, like on the wagon, will usually remain the same, the rears, not so.

Rear pressures in both wagons and utes can be really affected when towing. If your tow ball mass is on the heavy side, the back tyres naturally will be deserving of a few more kPas. Gotta prop up that fat arse!

The tyre is simply a pressure vessel, a container to hold the air that supports the weight of the vehicle. Weight is the critical object in this yarn.

Okay, there’s the tread pattern too, that steers the car and pumps the road dry when wet, but in this discussion, pressure is KING.

I mentioned towing ever-so-briefly before. A past blog piece I wrote explored what happens to a single axle caravan when the box and chassis weigh in excess of 2.5T. With 1,250kgs being carried per tyre, you ought to read how much air is required to make that work, read it here. If that doesn’t get you making the load connection in this argument, you’re smoking some seriously funny weed!

If your ute is empty, the last thing you’ll want is 250kPa or 300kPa in the back tyres.

At those pressures you’ll be reacting to every imperfection on the road surface, getting a bumpy ride and a whole bunch of other bad, like extended braking distances, increased puncture potential and faster wear on your tyres.

Let them down to the 200-220kPa mark and everything is right in the world again, a heaps-better ride, the shortest braking distances, fewer punctures and maximum tyre life.

The overwhelming majority of vehicles I come into contact with have over-inflated tyres and it shouldn’t be!

Your local tyre shop has to bump a fair bit of air into a new tyre when they fit them to a wheel, to seat the bead, the inner circumference of the tyre. Most will adjust them down to something more realistic, but sadly almost always in excess of what is required (the cynic in me thinks it’s because they’ll set you on the path to prematurely wearing them out sooner, so they’ll get the repeat business).

Your franchised car dealer will return your vehicle after service with their version of what’s best (which will vary from dealer to dealer, technician to technician), but it will always be at total odds with the placard provided by the vehicle maker they are representing, so there’s a conspiracy going on and it is not based on any science.

Maybe these same “experts” looking after your vehicle believe in the theory of Creation too?

I had my empty D-MAX return from service recently with a notable bump in pressure. It went in at a cold 200kPa or 29psi (what the placard said) and was returned to me with 280kPa or 41psi, front and rear. That’s a 40% increase!

I knew it from the steering feedback I was getting without having to look at my TPMS (tyre pressure monitoring system) and barely a hundred metres down the road, and I expected it, as it happens all the time. They had no answer when pressed for one, except I couldn’t help but remember the fully laden pressure on the placard for the rears was 280kpa. Lost in translation once more!

I also had a couple in a brand new MU-X a couple of weeks back and running those filthy 20” wheels that Isuzu are fitting for the ninety-percenters who don’t go bush. When I asked them how tight their tyres were, they shrugged, but they paid attention when the gauge showed 345kPa (50psi) and straight off the showroom floor! Ouch. That was a failure waiting to happen.

Some of you will say that you’ve fitted LT (Light Truck) tyres to your machine so the placard’s now inaccurate. Not so. Size for size and P (Passenger) versus LT makes little difference, because the loads are still the same. A minimum LT pressure in the TRA Manual might suggest 250kPa or 36psi, but that’ll likely be when carrying a load of 800kgs per tyre. If your truck is unladen, it’ll only be carrying around 500-600kgs per tyre, well under the minimum threshold.

Placards are there for a reason, to give mugs like us some guidance. I bet none of you ignore the oil level on your dipsticks do you?

GIPHY App Key not set. Please check settings